«Vyazma» at the international exhibition «Cleanexpo Moscow 2017»

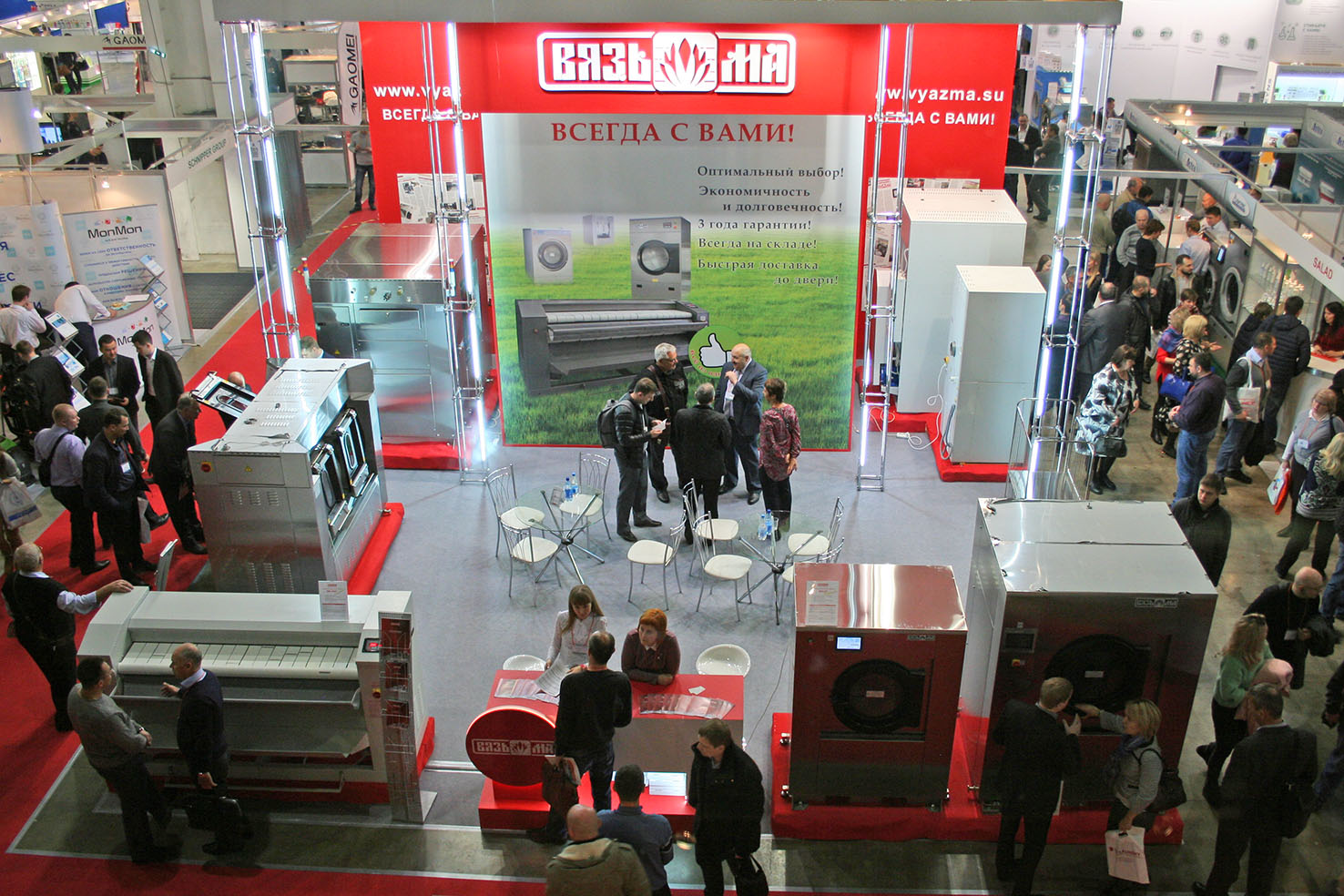

Booth of «VMZ» JSC at the international exhibition «CleanExpo Moscow 2017»

«Vyazma» had one of the largest booths at the exhibition this year. Bright and spacious booth was duly appreciated by visitors and other participants of the exhibition. Vyazma machine-building plant has created the most favorable conditions for visitors to get acquainted with laundry equipment.

7 machines were demonstrated at the booth. All of them are brand new! Among the new products of 2017, the plant presented the long-expected washer-extractors VO-25 and VO-50, equipping fully the model range of sprung machines in terms of load, filling the gaps in 25 and 50 kg load, respectively. From now on, our customers do not have to think hard of the machine to purchase: VO-40 for 40 kg or VO-60 for 60 kg of laundry loading, so that it is «none too much and none too little».

Ahead of the needs and wishes of our customers, we strive to offer the best and introduce innovative technologies continuously. For the example, laundry weighing option was first presented in washer-extractors VO-25 and VO-50, installed on the machines at the request of the customer. This option allows determination of precise laundry volume, loaded into the machine and set the program for the best quality of washing consequently. In addition, it provides for water and other resources saving, making the machine more efficient and environmentally friendly.

Booth of «VMZ» JSC at the international exhibition «CleanExpo Moscow 2017»

Booth of «VMZ» JSC at the international exhibition «CleanExpo Moscow 2017»

The model range of «barrier» type washer-extractors was enlarged with VB-60 (60 kg load) and VB-70 (70 kg load). The first one was presented at the last exhibition in 2016. Read more about it in the last year article. Here is VB-70 - a new model of 2017. Unlike the preceding VB-60, this model has a drum seperated into 2 parts not longitudinally, but transversely, similar to VB-100 machine. Each drum section has an appropriate tilt angle, ensuring convenient loading and unloading of laundry. The concept is that the drum section is positioned at a downward slope at loading and feeding of laundry inside the drum is convenient. At the end of the washing and spinning process, the drum position is changed to the unloading mode, where the drum section is «outward» to the loading door, facilitating unloading of laundry from the machine. This structure of drum sections facilitates greately the work of the laundry staff, especially when it comes to large loading volumes.

In this model, as well as in all «barrier» type washer-extractors, laundry is loaded and unloaded from different zones. As a rule, there is a wall between the zones, the barrier-type machines are mounted in. Thus, there is a division into a dirty zone – where the laundry is loaded into the washing machine and a «clean» one -where the washed laundry is unloaded from the machine. Such machine is indispensable for medical institutions, or institutions of nuclear, chemical, electronic industry and other industries, where compliance with sanitary and hygienic standards of clean linen is of special importance.

VB-70 is equipped with a touch controller with a large color screen. The controller is completely in Russian with an intuitive interface. Memory capacity is for 50 programs, 10 of which are factory pre-installed, and user can configure the other ones at his own discretion. The machine has outlets for connection of 6 dosing pumps. They are operated from the machine controller directly and do not need purchase of an additional control unit.

Controller with residual moisture function (left), residual moisture sensor installed on the machine (right)

The next novelty was VS-75 drying machine for 75 kg of laundry loading. Its drum volume is 1500 liters! It is used to dry massive things and even small carpets, since the drum diameter is 1300 mm and its depth is 1130 mm.

Control of the machine is similar to previous models of «Vega» drying machines. But the controller herein is not built into the case, but brought forward on a special «stand». Thus, the controller screen is positioned at an angle comfortable for the user. The installed machine controller is of a later version with 25 adjustable programs + 5 standard factory programs, adjustable as well. The residual moisture sensor and precise temperature control simplify the drying process to a great extent. Automatic drum reverse and the «CoolDown» cooling system reduce probability of folds and facilitate finishing. Filters are behind the lower part of the front panel, equipped with two handles, allowing the operator open it and remove the filter for cleaning easily.

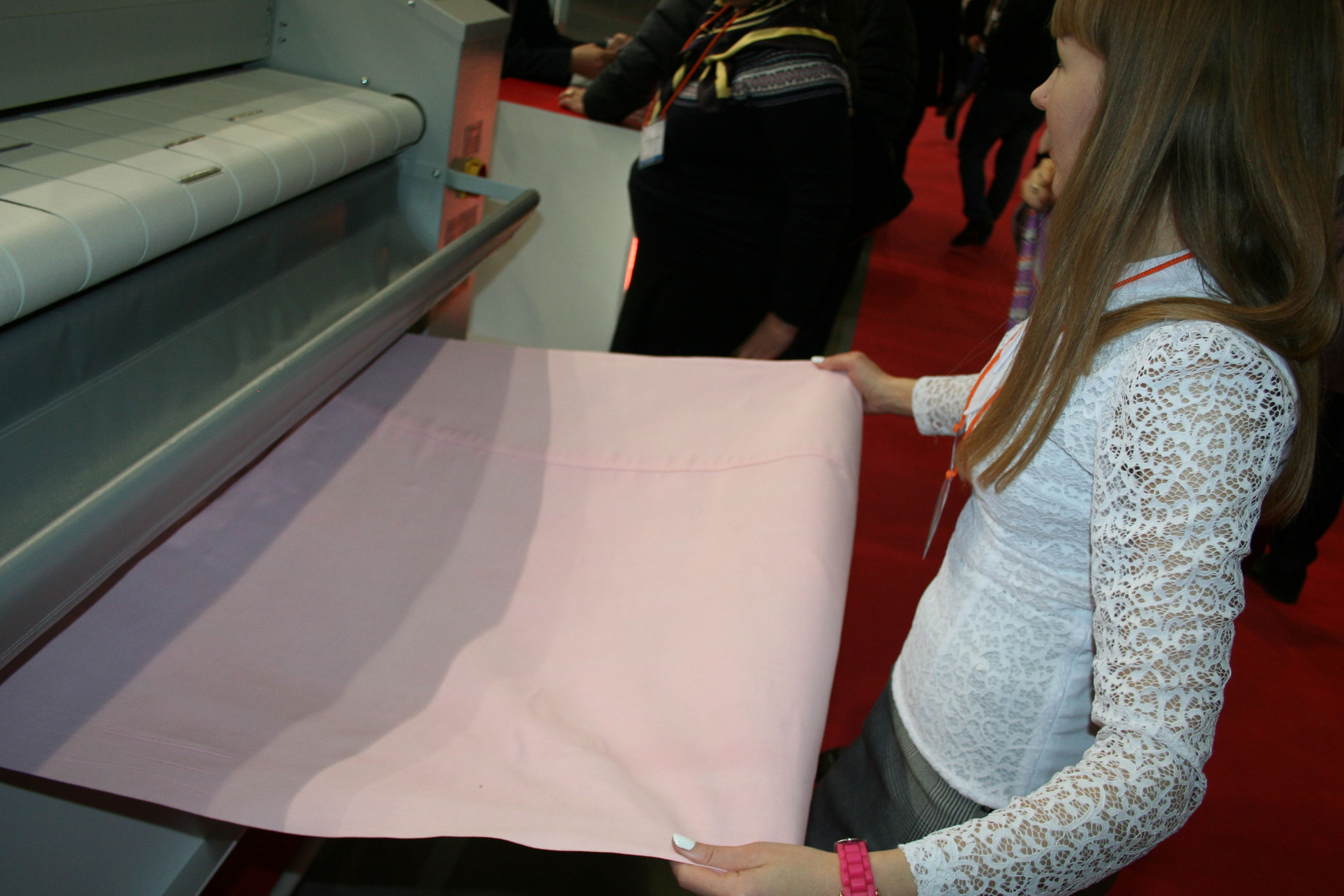

Ironing calender VK-1840 of new «Vega» series with a chrome-plated ironing shaft, improved design, weight and size dimensions, was demonstrated in operation at the booth. The new calender is an ambassador of «Vyazma» calenders. VK-1840 demonstrated excellent performance indexes (up to 50 kg / hour) and excellent quality of ironing, of which the visitors of the booth made sure with their own eyes.

Mass production of all new products of the plant will start from 2018. However, the plant has already got a pre-order for production of 5 VS-75 drying machines.

A seminar was held during the exhibition to talk about the history of the plant development, the model range and its competitive advantages.

The hall for 60 people was full, evidencing a high interest in «VYAZMA» equipment. Everyone could study in detail the products of the plant, learn their features, differences between the models of «VYAZMA» equipment and the latest innovations. In addition, visitors learned about the main advantages of the equipment, such as the best price-quality ratio, the advantages of automatic control of the laundry washing process, the advanced features of controllers, possible connection of dosing pumps for liquid detergents, and the new laundry weighing option. Our customers are aware that spare parts and ready-made equipment are always in stock, and shipment is done within 3 days from the date of payment.

With the existing economic slowdown, saving and the most efficient use of available funds are particularly topical. A lot of customers have already made sure that some manufacturers of laundry equipment «play up» with this situation and mislead the consumer, selling practically «bare» equipment. Parameters of cheaper brands do not correspond to the stated reality often. Such washer-extractors cannot spin the laundry completely due to the very rigid suspension system of the drum and strong vibration of the machine. This is «one-time» equipment in fact due to its low maintainability, operating until its first serious failure. Purchase of «VYAZMA» equipment avoids all these problems, and this is our main competitive advantage.

Vyazma machine-building plant pays much attention to after-sales service and service backup of the supplied equipment, thus this was the topic covered by the second part of the seminar. Head of the plant service department was the speaker. He touched upon the current topics on equipment commissioning, warranty and post-warranty service.

He recalled the importance of signed service contract in this report. After all, with such contract signed, the client gets prompt and qualified assistance in solving issues related to commissioning, training of personnel on «Vyazma» industrial laundry equipment operation and, most importantly, a 36-month warranty with possible equipment maintenance during both the warranty period and in the post-warranty period from one year to several years, all for a small fee. At the same time, when buying Vyazma equipment, you may choose a service center presented in your region as a service company, or sign a service contract with the manufacturer directly. The factory has a hotline and a special mobile team, ensuring prompt assistance in troubleshooting technical problems of laundry equipment.

Vyazma machine-building plant provides maintenance of the supplied equipment during the entire period of its operation, i. e. until its full depreciation, which is 10 years usually. All the while, the plant and the certified service centers carry out service and maintenance.

Maintenance service system of the plant includes the entire range of services: supply of spare parts, technical documentation, provision of repair work, training of specialists, study of the equipment efficiency, identification of its strengths and weaknesses, upgrade of the serviced equipment, etc.

Visitors had chance to ask all their questions at the seminar. All participants received the bags with information about the plant products and souvenirs.

Meeting with dealers at the conference «Factory to dealer, dealer to factory» is a traditional event during the exhibition.

Best dealers were awarded in a solemn ceremony, preliminary working results for 2017 summed up and plans for 2018 outlined.

No doubt that Vyazma plant participated in «CleanExpo Moscow 2017» exhibition at the highest professional level and this event is memorized for a long time as a beautiful, informative and useful one. First of all, it was useful for market trends identification and determination of the further growth vector of the plant. After all, Vyazma efforts are to make work and business of our clients more convenient and profitable.

Welcome to future exhibitions, they will be no less interesting!

215110 Russia, Smolensk region

Vyazma, 25th October Str., h. 37

Tel: +7 (48131) 3-48-12

E-mail: vmz@vyazma.su