«Vyazma» at exhibitions in Moscow 2016

INTERNATIONAL EXHIBITION «CLEANEXPO MOSCOW 2016»

November 9-11, 2016.

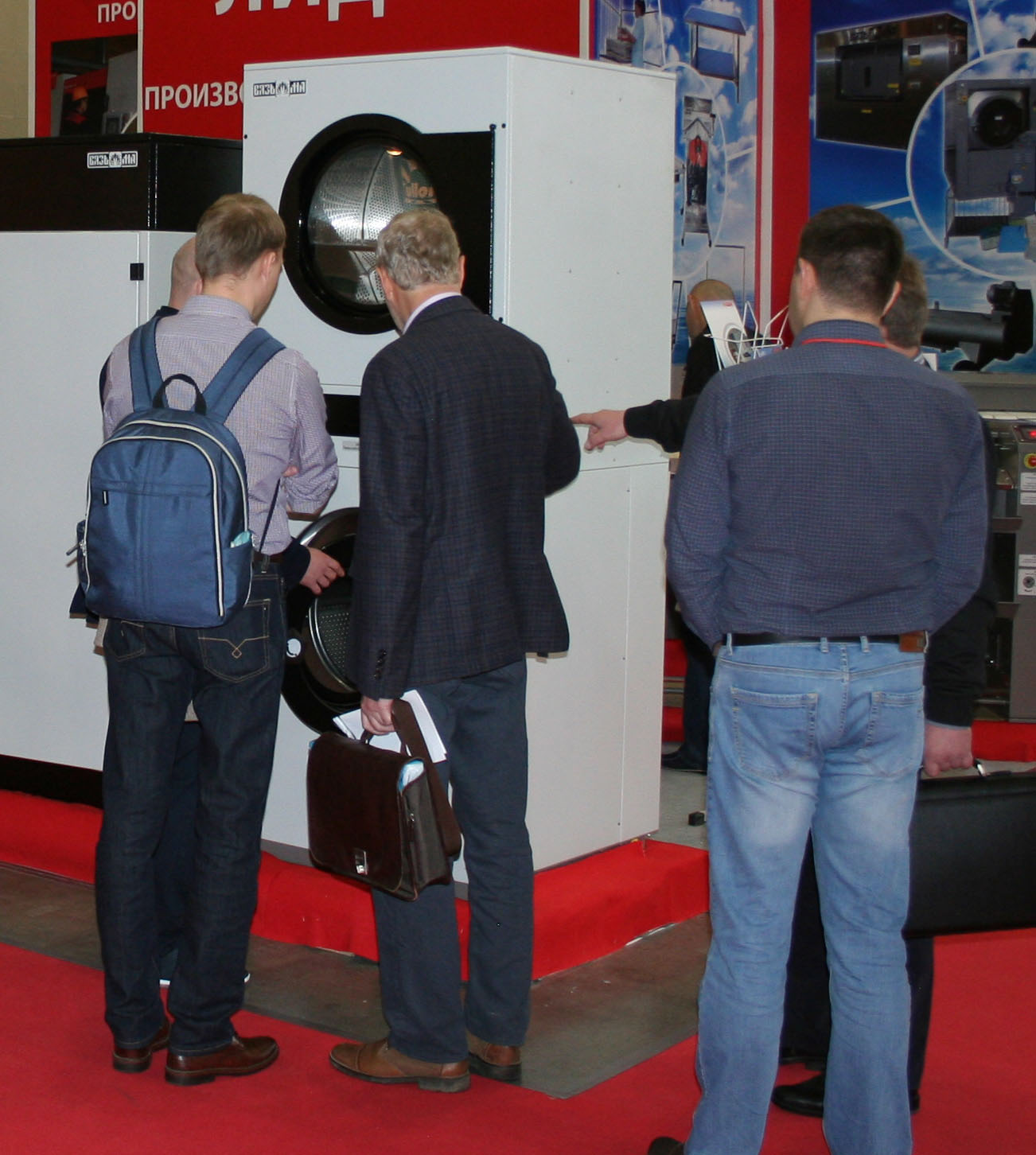

The booth of Vyazma machine-building plant presented most of new products at the international specialized exhibition CleanExpo Moscow-2016.

Dealers and partners of «VMZ» JSC in front of the booth

«The leader in production of equipment for laundries and dry cleaners» - this slogan is a perfect characteristics of Vyazma machine-building plant. Continuous development, research and development work, improvement of existing and design of new products, a three-year warranty on all supplied equipment -this is what Vyazma is today. On top of it, Vyazma is a branched dealer and service network, covering all of Russia and the CIS countries.

The entire floor was for new products, plenty of which were presented this year.

VSSK-10 -professional dual machine (washing + drying) with 10 kg load each

1. VSSK-10 -specially designed for mini-laundries, professional dual machine (washing + drying) with a load of 10 kg each. The model has microprocessor control and large doors for convenient loading and unloading of laundry. The drum volume of the washing machine of this model is 100 liters, and that of the dryer is 200 liters! This is a real 10 kg load, unlike that of the foreign analogues, which, being presented as ten-kilogram have the drum with the volume for just 8 or 9 kg processing without tamping. Moreover, these are semi-professional machines, not designed for long-term round-the-clock operation.

VSSK-10 needs no floor fixing and occupies the floor space of 0.7 m2 only! This is a perfect solution to keep your laundry clean in a restricted floor space. VSSK-10 dimensions are just (WxDxH) 1070x650x1985 mm, the weight does not exceed 450 kg.

Barrier» type washer-extractor VB-60

2. «Barrier» type washer-extractor VB-60 of «Vega» series with stainless steel facings for 60 kg load of laundry. The automated washer-extractor for industrial use is designed for washing, rinsing, spinning and shaking of laundry. The design feature of this model is the drum divided into two parts of 30 kg with separate loading doors. The «pullman» type drum contributes to a more even load distribution when washing and extracting laundry. This model provides for loading and unloading of linen from different areas (in rooms divided by a wall) in order to comply with sanitary and hygienic norms for clean linen in medical institutions or companies of nuclear, chemical, electronic industry and other fields. The automatic control system with a touch-sensitive control panel has a memory capacity of up to 50 washing programs, 10 of which are factory preset, and the users can configure the rest at his own discretion. This controller is adapted to connect and control the system of dosing pumps for liquid detergents.

Ozonizing cabinet VSHO-1

3. VSHO-1 ozonizing cabinet was one of the most unexpected and radical innovations at Vyazma booth. It is a device with ozone generator, ensuring fast ozone concentration in a closed sealed space, which contributes to elimination of viruses, bacteria and odors accordingly. Ozone is a natural gas with strongly pronounced antibacterial properties, killing fungal compounds, yeast and viruses. The antibacterial effect of ozone exceeds 600 times that of chlorine. At the end of the ozonation cycle, the cabinet is purged with air from the premise and release into the exhaust ventilation. Thus, the ozonation process is completely eco-friendly and safe for the staff, as the cabinet itself is fully sealed. As for ozone, it decomposes fully in half an hour after removal to ventilation. Finally, it may be said that ozonation is the safest and most efficient non-contact method of cleaning various products (clothing, shoes, etc.).

Since ozonation is done without mechanical shear, products are processed without risk of damage. Such cleaning process can be used for products, machining of which is not acceptable or involves the risk of defects. These products are fur coats made of expensive furs, hats, theatrical costumes to be refreshed, as well as sports equipment and shoes.

Walter Cividini, the Managing Director of «Fimas», a partner company of «VMZ» JSC, demonstrates operation of LPR-387.50 ironing press

VSHO-1 cabinet has a programmable controller, allowing to set ozonation (from 5 to 50 minutes) and purging period. Products are placed inside the cabinet: shoes and hats on removable shelves, and clothes on hangers on a crossbar. The cabinet doors are closed and locked at program start until the latter is fully completed. An important thing of processing in the ozonizing cabinet is to place things straight and provide a gap between them for ozone to pass smoothly. As such, the greater the density of products, the longer the treatment process is.

VSHO-1 cabinet can operate in the «easy drying» mode thanks to the built-in infrared heater. The cabinet operates from conventional 220 volt socket and consumes about 300 watt of electricity, is equipped with swivel wheels and has dimensions (WxDxH) of 1070x650x1985 mm, thus may be rolled through a standard doorway.

4. LPR-387.50 collar press was demonstrated at the exhibition together with «Fimas», the official Italian partner. This is an automatic press for final treatment of collars and upturns, complete with a steam generator (25 l), a condensate tank and an air compressor. It will ensure not only high performance, reliability and cost-effectiveness, but also high-quality processing, since there is no product deformation during ironing. The most simplicity of operation and maintenance will complement the pleasure of using the LPR-387.50 press in your laundry.

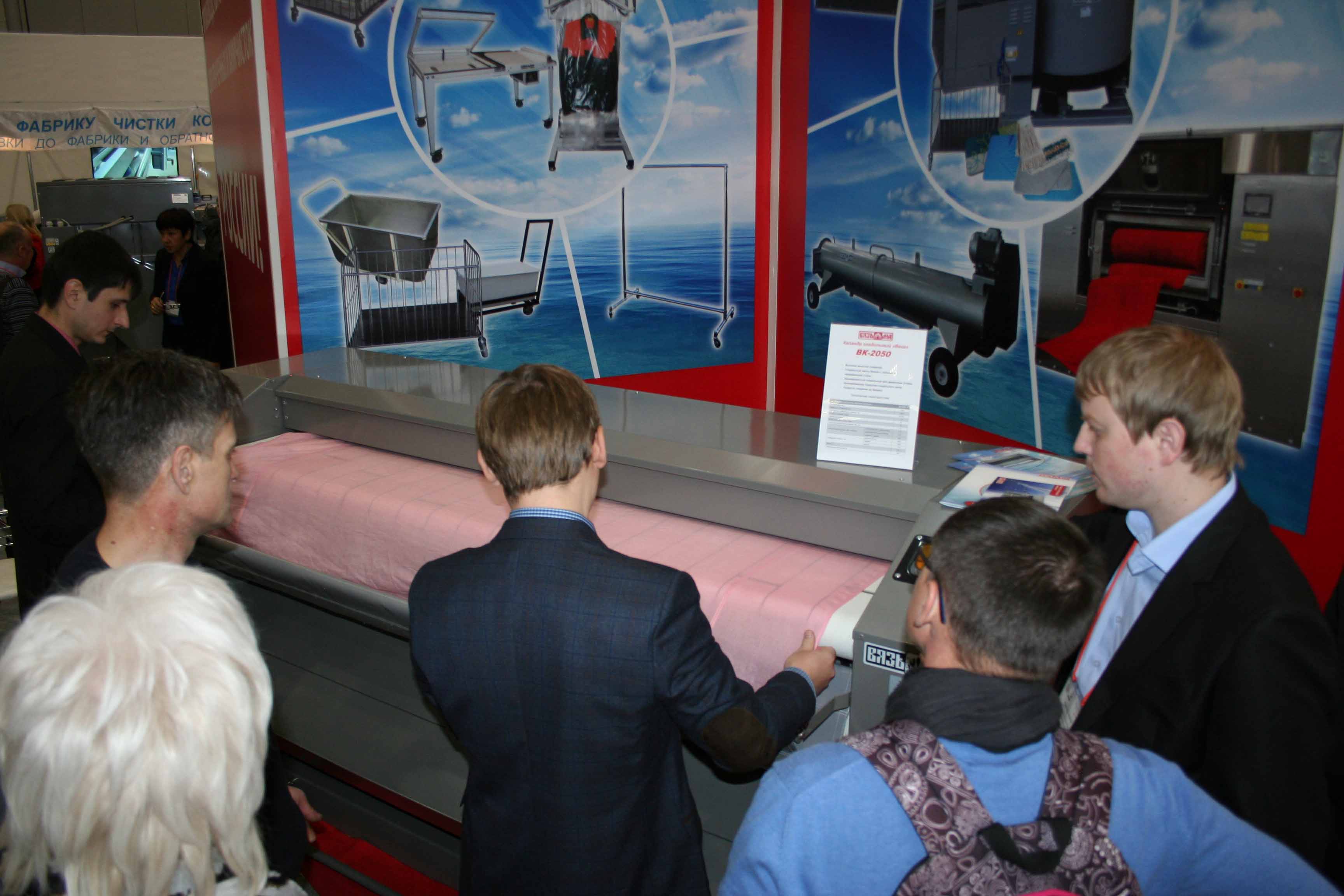

Demonstration of VK-2050 ironing calender in operation at the booth of «VMZ» JSC

Apart from the new products, VS-30 30 kg load drying machine of «Vega» series and ironing equipment: VG-2030 roller and VK-2050 calender. were presented at the booth. The latter were demonstrated in operation right at the booth, and visitors could see with their own eyes the ironing quality of the equipment, as well as the difference between the roller and the calender, which irons and dries laundry in parallel.

The exhibition was a success for the plant. The booth was next to the entrance to the exhibition and drew attention at once with its bright, beautiful design and its dimensions. It turned to be one of the most visited booths at the exhibition. Visitors were surprised with the new products presented.

Full range of equipment for laundries and dry cleaners produced by the plant, its continuous enlargement and reasonable price make it possible for «VYAZMA» to strengthen its position every year, enter new market segments, and existing customer demand acknowledges that

«Vyazma is a leader in production of equipment for laundries and dry cleaners in Russia».

«VYAZMA» AT THE 5TH INTERNATIONAL EXHIBITION «HOTEL EXPO»

October 17-20, 2016.

Moscow exhibition complex «Crocus Expo» hosted the regular exhibition «HOTEL EXPO» on October 17 - 20. It occupied three pavilions of the complex with plenty of visitors and the same number of interesting events as usual. This year was the second one for Vyazma machine-building plant participating in «HOTEL EXPO» exhibitions.

«Vyazma» participated with a new booth design and time-tested reliable equipment. Such equipment serves as a «workhorse» in hotel laundries of any level.

VO-15 washer-extractor of «Vega» series with stainless steel facings for 15 kg load of laundry was presented at the booth. This model belongs to a series of high-speed washer-extractors with final extraction (G-factor of extraction up to 400), ensuring laundry with a 50 % residual moisture at the end of the washing procedure, thus there is no need to use a centrifuge in the process chain. Another distinctive feature of this series of machines is the sprung independent drum suspension. Machines of VO series have a conceptionally new type of drive control: frequency control of the asynchronous electric drives. This provides smooth acceleration of the drum to the spin speed, reducing the load on the structural elements and the foundation, as well as vibration, and the machine is near-silent in operation. The automatic system with a touch-sensitive control panel has a memory capacity of up to 50 washing programs, 10 of which are factory preset, and user can configure the rest at his own discretion. This controller is adapted to connect and control the system of dosing pumps for liquid detergents. The basic parts of the machine structure, as well as the inner and outer drum and facings (or the front facing only, depending on the order option) are made of stainless steel, increasing structural durability.

Exhibition booth of «VMZ» JSC at the international exhibition «HOTEL EXPO 2016»

Packing table USSB-2.63

There was VS-15 drying machine of «Vega» series with a 15 kg load nearby. «VEGA» series is a new generation of industrial drying machines made of high-quality materials and components , using the up-to-date technological equipment. Drying machines are designed for drying laundry, with automatic control (10 programs), filter clogging alarm and cold air purge mode. «Vega» series drying machines are compact in size and equipped with a motor with a reverse function. All machines have residual moisture sensors as standard.

As for ironing equipment, VG-1630 roller was at the booth. VG type electric heated, single-side maintenance ironing rollers are designed for ironing of straight linen with a residual moisture content of 25% max, made of polyester fiber, wool, silk, cotton or linen. Electronic control system of the rollers provides for smooth speed adjustment up to 5 m / min and temperature in the range from 100 to 2000C. SPRINGPRESS spring winding (Belgium origin) is used for shaft winding in the ironing rollers. This eliminates early winding shrinkage, increases the shaft down force, and improves the quality of products ironing as a consequence. Being efficient, compact and reliable, these machines can complete a laundry room for 100 kg / shift.

Packaging equipment, namely the USSB-2.63 packaging table, was demonstrated in operation at the booth for the first time. It is designed for thermal sealing of stacked clean laundry in plastic film bags in half-sleeve form with a width of up to 650 mm. The table has a control unit, allowing adjustment of sealing time for different film thicknesses. Automatic sealing activation with the pressure plate lowered and held, ensures easy operation of the packaging table. Thus, the process of laundry packing is simplified to the maximum, and takes a minimum time. Sealing a stack of laundry with a wrapping film takes from 3 to 10 seconds, depending on wrapping film thickness! This simplifies the laundry packing process by times and increases performance substantially.

A new shelf-stand container SN-600 was demonstrated at the booth as well, the plant started its manufacture in the spring of 2016. The mobile shelf-stand container is mounted on 4 swivel wheels. Done of stainless steel. Has opening doors with safety locks. It is made in two versions: with netted and «solid» shelves. This rack is very convenient and no doubt useful in any laundry!

«HOTEL EXPO» Exhibition was held at a high professional level in general. «Vyazma machine-building plant» booth was the largest at the exhibition and one of the most visited. It should be mentioned seperately that the plant pays special attention to quality; warranty for all products manufactured by the plant is 3 years currently!

Visitors of the exhibition were directors and managers of various levels, representing different companies and, of course, the hotel business, from Sevastopol, Irkutsk, Yakutsk, Kostroma, Chelyabinsk, Saratov, St. Petersburg, Moscow and other cities of Russia, as well as cities of the CIS countries-Bishkek and Tashkent.

A fairly large number of companies came out recently, that used to work with foreign equipment and are eager to change to the domestic one. This acknowledges the right development path of the plant. Such positive trend can not but make happy, and it empowers us to improve further, using a steady development strategy.

215110 Russia, Smolensk region

Vyazma, 25th October Str., h. 37

Tel: +7 (48131) 3-48-12

E-mail: vmz@vyazma.su