«Vyazma» at the exhibition in Moscow 2014: the present and the future of the russian plant

The leading Russian industry exhibition, called CleanExpo Moscow now, was held in the Moscow exhibition center «Crocus Expo» on October 21- 23, 2014, and JSC «Vyazma machine-building plant» became one of its main actors. «Vyazma» was the only company among the manufacturers of equipment for the enterprises of our industry, that did not miss a single specialized exhibition in Moscow, and this is the best sign of its stability and reliability. At the same time, it is a must for Vyazma machine-building plant to bring at least one, and more often several new products, of permanent interest of the visitors, for each regular Moscow exhibition. This is the most to reflect the dynamics of the plant development, its continuous progress, and its activities to improve its products.

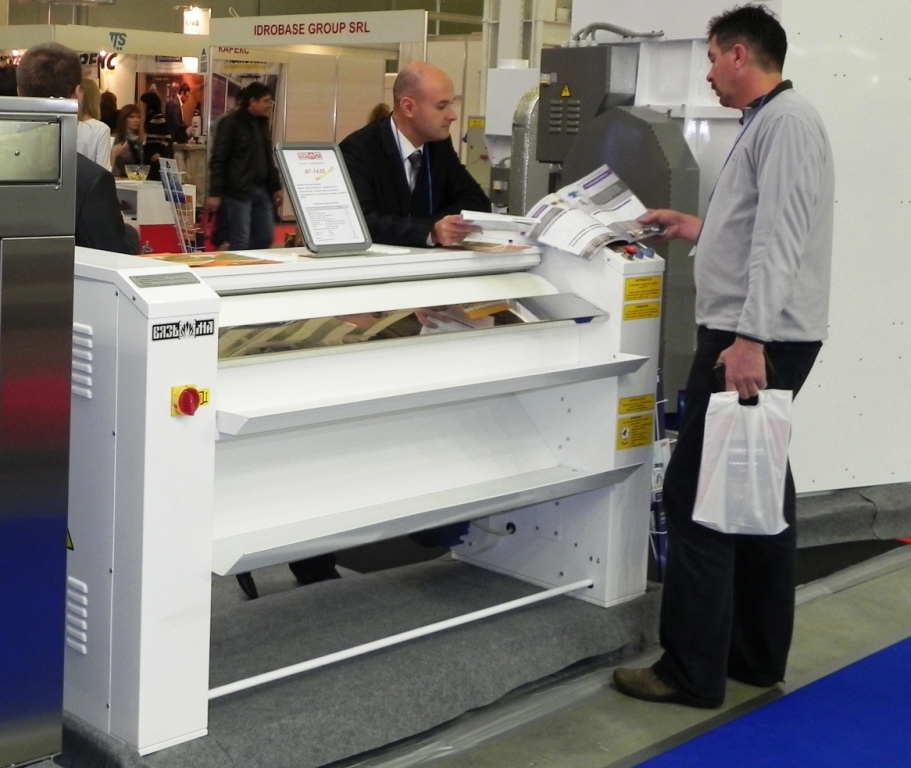

The booth of Vyazma machine-building plant at CleanExpo Moscow-2014 exhibition.

This work approach is driven by the company status. Indeed, «Vyazma» today is almost the only local manufacturer of equipment for dry cleaning and laundry and, of course, the only Russian plant to provide equipment package for the enterprises of our industry. And that being the case, Vyazma machine-building plant consideres it its duty to report annually on the performed work and does it clearly: you can view, study each new product and ask all questions to its developers..

«Vyazma» presented a record number of units of its new products at the exhibition in Moscow in 2014.

VCK-2440 carpet spinning centrifuge. The plant started production of the special-purpose equipment for processing carpets and carpet rolls, and the «first sign» is the centrifuge VCK-2440. Its inner drum is made of stainless steel (the outer drum and the body are powder enamel), and it has a frequency control of the motor speed. The centrifuge extracts carpets up to 6 m long and up to 2.4 m wide. It is a wheeled centrifuge: it can be easily moved from place to place, and it does not need a rigid fixing to the floor.

Washer-extractor VO-100P. The family of sprung washer-extractors «Vyazma» of VO series was supplemented by the machine with a high-speed spinning and 100 kg load (previously, the model of this load was replaced by the products of the plant partners). Now VO product range includes loading machines of 8, 15, 20, 30, 40, 60 and 100 kg, covering the entire demand for this type of machine. With its sizeable load, VO-100P machine is quite compact and occupies less than 3 m2 of the floor space. The machine is made of stainless steel, has a touch screen control and option to connect dosing pumps for liquid detergents supply.

VCR-10 drying machine with heat recovery. In 2014 «Vyazma» plant started production of extremely economical drying drums, ensuring substantial saving of thermal energy cost, and thus acknowledged once again its affiliation to the world leaders in production of machines in this segment.

VCR drying drums are equipped with a heat recovery system: warm air from the drying machine enters a special heat exchanger, where it heats the cold air from the outside, thereby saving energy for drying and increasing its productivity. As a result, heat energy saving with no loss of the drying machine performance comes to 25%, for VCR-10 drum it was 60.000 rubles price-wise at the time of the exhibition.

VS-40 drying machine. «Vega» series drying machines family enlarged with one unit, now comprising models with 10, 15, 20, 25, 30, 40 и 50 kg load. Like its «sisters» in the series, VS-40 machine has a scrub drum, an engine overload alarm and a filter clogging alarm, as well as a scrubber and a cold air purge function. «Vega» drying machines are compact in size, simple and easy to operate and maintain, as well as have a built-in residual moisture sensor as standard, and fully comply with modern requirements for professional drying equipment.

VG-1430 ironing roller. It has a 1,4 m width of the working ironing surface and is an important supplement to the existing series of VG rollers range with working widths of 1000, 1200, 1600 and 2000 mm. The ironing surface is made of chrome-plated steel; the 300 mm diameter shaft has a Springpress spring winding, increasing its life cycle and ironing quality. Ironing rollers of VG series have variable temperature and ironing speed, electronic protection against overheating of the ironing surface and are represented by five positions now, as already mentioned above. Rollers with a width of 1 and 1.2 m are equipped with 180 mm shaft, the rest, including the new VG-1430 roller, have a 300-mm ironing shaft.

The plant has launched mass production of a packaging table and an outer clothing packaging machine for dry cleaners and laundries, which pack washed and ironed laundry into bags for delivery to the customer. Nobody produced this type of product before VMZ in Russia, and sometimes customers had to wait 2-3 months from the date of prepayment to order foreign products of this type. This equipment is being tested currently and will be manufactured to stock next year, in order to minimize the delivery time of these products to the end user. Naturally, the price will be lower compared to foreign analogues.

Even though the LB-40 washer-extractor, presented at Moscow exhibition, is nominally not a new one any more, here are a few words about this family of «Vyazma» machines. Today, the Russian plant produces high-speed barrier machines in the range of 20, 30, 40 and 240 kg loads. These machines are in successful operation at a number of Russian enterprises and proved themselves to be positive from the standpoint of reliability and functionality.

It is obvious that this loading range requires additional positions, meaning there is room for improvement.

Coming back to the idea voiced at the beginning of our article, let us summarize the main outcome of CleanExpo Moscow – 2014 exhibition for Vyazma machine-building plant. During the exhibition in the IEC «Crocus Expo» «Vyazma» evidenced its belonging to the leaders of professional laundry equipment manufacture and showed that it gets with the times and looks ahead to the future with reasonable optimism. Hence, looking forward to the news from Vyazma and new industrial events!

All of the above new products are listed in the price list posted on the website and are available to promise.

«Dry Cleaning and Laundry» Magazine (No. 4, 2014)

215110 Russia, Smolensk region

Vyazma, 25th October Str., h. 37

Tel: +7 (48131) 3-48-12

E-mail: vmz@vyazma.su