Laundry equipment commissioning and start-up with one's own hands?

The second step following the new laundry equipment purchase is professionally done check out and start up. It is no secret that such work requires highly qualified specialists, but many customers neglect recommendations and try to set up the equipment on their own. V.A. Golubev, Deputy General Director, Head of the engineering center of Vyazma machine-building plant, talks about the consequences of the above, as well as about the procedure of installation, some difficulties and details of equipment commissioning.

- Viktor Alekseevich, could you please us what the client should pay attention to before start-up and adjustment execution?

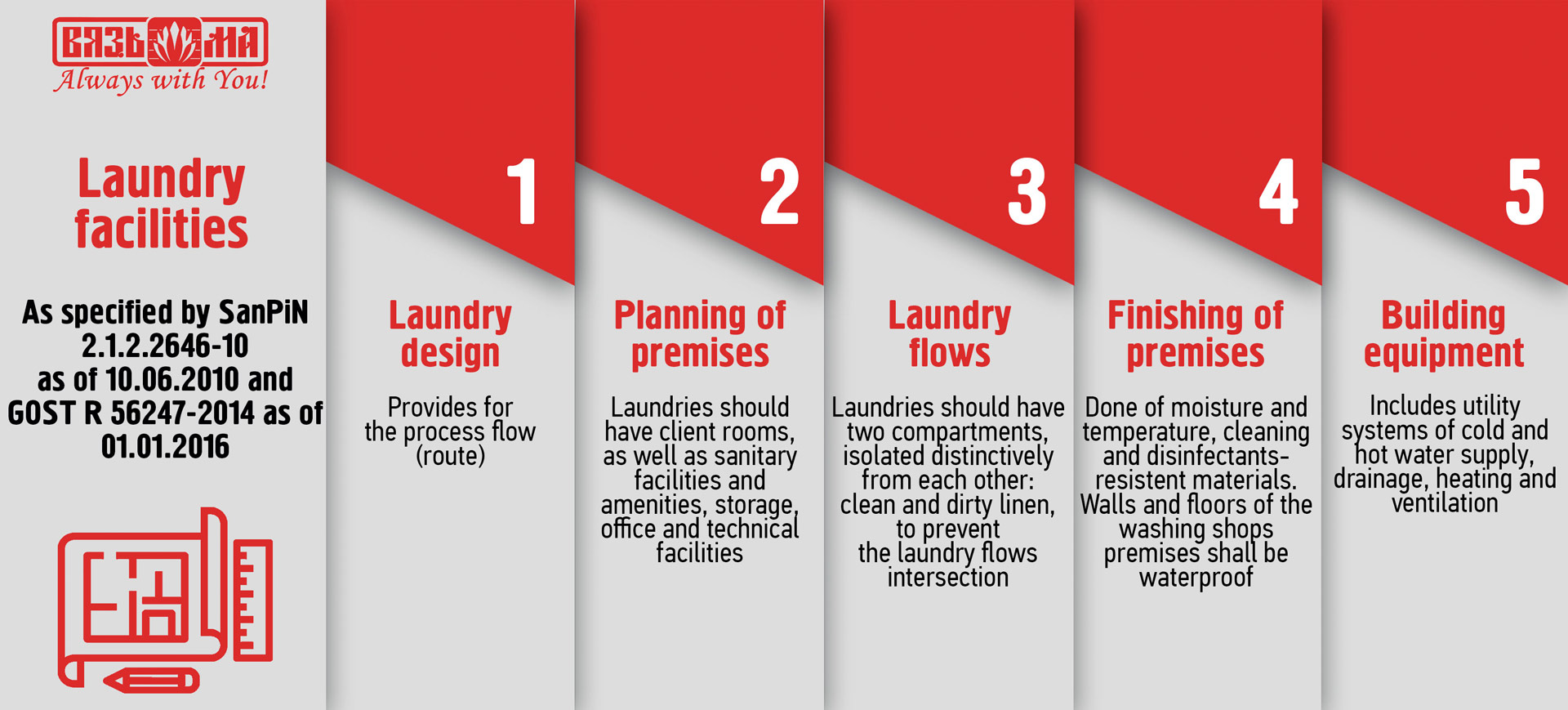

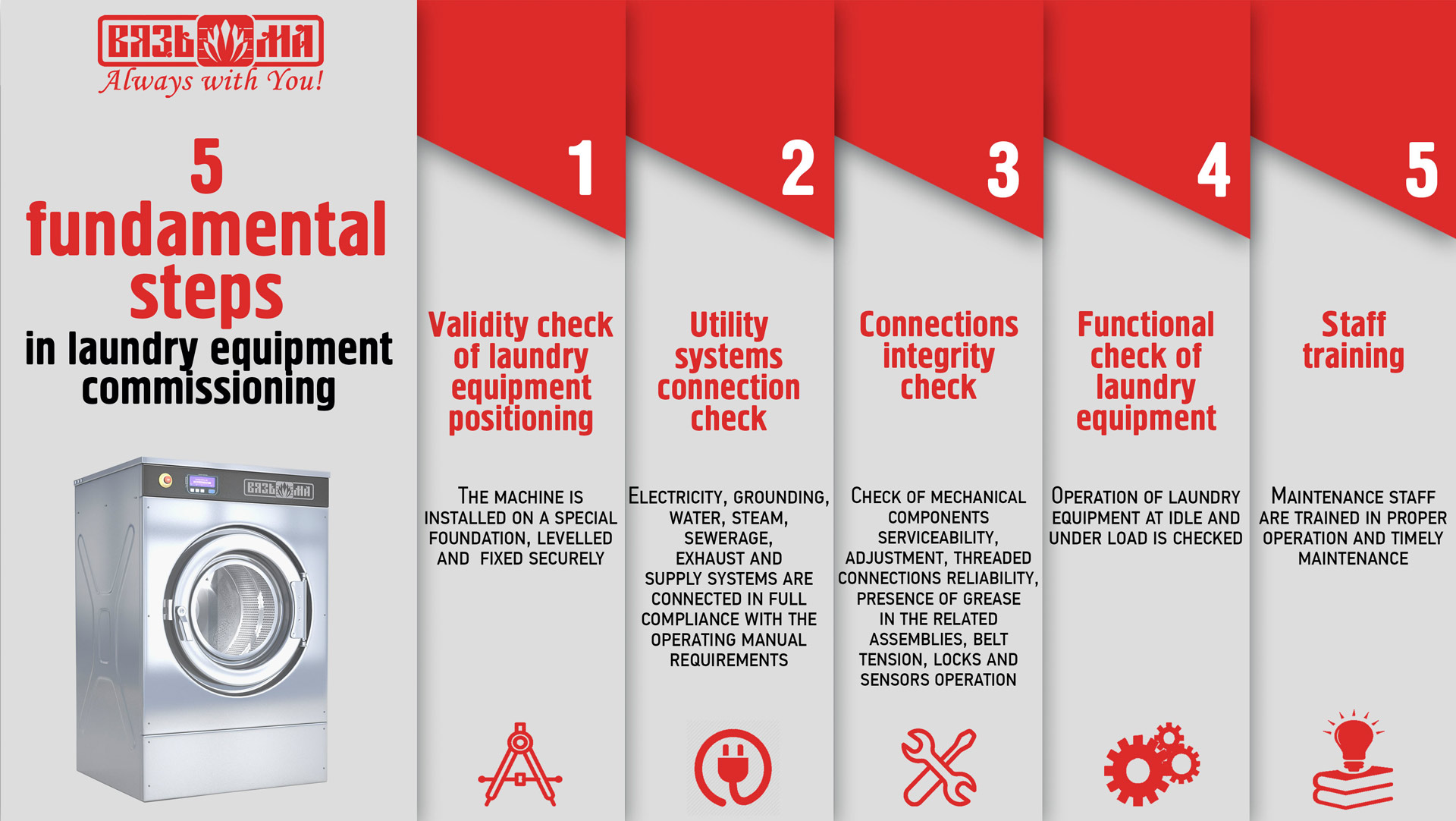

– The first thing you need to do when starting a laundry is to check the room: see if there are doorways to bring in the equipment, study the floor composition (whether you can use anchor bolts to fix the washing machines or you need to make the foundation first), and so on. All our requirements are set out in the user manual: there is an assembly drawing and all work should be carried out in full compliance with it.

It is also necessary to check supply of hot and cold water, drainage, ventilation and electricity. Talking about water supply, pay attention to the filters installed. A new water supply system is a rare thing, most often conditions of the pipe fittings, the pipes themselves leave room for improvement: scale and rust, clogging the valve, get into the water. Therefore, we recommend installing fine filters to ensure clean water supplied into the washing machine.

– Are there some nuances when connecting to the ventilation system as well?

- For sure. Connecting the equipment to the ventilation system is no small matter. For example, a steam and foam vent should be installed for washing machines: it should be connected either to a retractable ventilation system, or to a drain system, which is acceptable; not tight, but with a gap, so that there is no vacuum in the machine during the «Drain» operation. A must for the drying machines operation is a nice supply-extract system, ensuring efficient drying. Many people plenty of mistakes: for example, they can not make additional ventilation, or they do not want to and do not find it necessary. This results in increased load on the equipment finally, and its failure afterwards.

- Installation works comprise connecting the equipment to power supply as well. What shall be observed herein?

– First of all, check whether there is enough electrical power for complete equipment operation, as well as that feeder cables fit this power. When supplying electric power, pay attention to the distribution equipment (which automatic switches or safety devices should be installed there). All of them shall meet the rated power of the installed equipment. Then, install a power cord as it is set out in the operating manual. It is also worth noting that the connection standard has surely changed: previously, power-up was four-wire, now it is five – wire (you need to have three phases, 380 V, as well as a neutral wire and a separate ground connection). A number of users still practice zero -earth combination, which is wrong. Some laundries do not pay due attention to grounding of equipment as well, which affects performance of controllers, frequency converters, and even heating elements: additional potential is created, which influences operation reliability of these elements.

- Who can perform such works?

- First of all, these are mechanics and electricians. We have do-all specialists: they are knowledgable of both mechanics and electrics; they know how to set up a frequency converter, controller, how to identify and correct faults.

We check everything, as further operating conditions of our equipment do matter for us. A lot of people can say that everything is fine, and you can not understand that this is actually the case until you check it personally.

– Can the client carry out the commissioning work himself?

– They can do it for sure subject to sufficient qualifications of service personnel: education, experience, knowledge of the laundry equipment functioning details. We do not put obstacles for that. However, experience has proven frequent cases of faulty utilities supply, installation and equipment fixation at unassisted execution of commissioning works.

– Did it happen that a person opened his laundry and started setting up the equipment on his own, but it did not work out and he had to call for the plant specialists?

- Yes, these are frequent cases. Everyone tries to save money, and then calls the factory and ask, for example, the reason for the fan in the dryer or ironing machine blow in the opposite direction? It turns out that the electrician of the laundry mixed up the phases at connection. There are plenty of similar examples.

The main guarantee of reliable and long - life operation of any professional equipment is its proper installation and current maintenance by qualified specialists

Quality of equipment operation depends largely on its proper installation; at the same time, customers usually install the machines in premises they have at hand, which are not always convenient from the point of view of installation: these can be basements, semi-basements, rooms with no large doors, etc. Everyone takes the equipment in as he can. There was a case when the washing machine was dragged through the window, and when installed and connected, it did not work due electrical components damage. As it turned out later, they just dropped the machine while carrying, and tried to present the emerged malfunction as a guarantee event.

Here is another example: the customer saved on installation and commissioning and installed the ironing calender on his own. During operation, the ironing tapes started to gradually shift to one side, and the bearings creaked. A few weeks later, the ironing tapes worn out and needed replacement, although their useful life is one year. The client began to call the factory, swearing. Service specialists were sent to the site, who found out that the calender was simply not levelled, the tapes started to shift due to the tilt and oil leaked out of the bearings. Our specialists eliminated failures caused by incompetent commissioning: they installed the calender as it should be, that is levelled, lubricated the bearings, and all failures were settled.

Of course, it is strange for us that respected mature persons, businessmen, spend hundreds of thousands and even millions of rubles to buy process complicated professional equipment, saving on qualified services of the maintenance personnel for equipment installation and adjustment in the meantime, while losing many times over on idle time and repair of improperly installed equipment.

–If the client still wants to save money and does the commissioning himself, is he still calling the plant for some issues?

– There are a lot of such calls and letters. There are failures in operation, and the client can not understand the reason. We pay a lot of attention to these issues, tell and explain them the reason for the failure to occur, and still advise to sign a maintenance contract with a designated company.

– Does it happen that a customer, eager to open a laundry comes to the plant to get trained?

- There were such cases. But there is such a nuance in this case, the one who wants everything to work properly, does everything to avoid the headache. The one who does not want it, looks for a reason and an excuse. For example, many people nowadays practice operation of our equipment around the clock, and they «have no time» to stop the equipment in order to simply clean the dust, lubricate it, and inspect. Naturally, it is not the operation the plant recommends. The equipment is sure to stand it, and we are surprised that it has worked that long without proper maintenance.

– Do your specialists have to explain to the client not only the procedure of commissioning, but also the detergents to be used or the details to pay attention to when operating the equipment?

– Of course, the staff is also trained to operate the laundry equipment along with equipment setup during the start-up and adjustment works. We explain the laundry load, the way to program, to work with the controller, to check the frequency meter settings, to configure the vibration sensor and what it is needed for, as well as what detergents to use for washing. For example, there is a tendency now to use liquid detergents, and the dispenser needs to be connected for their use.

We check everything, as further operating conditions of our equipment do matter for us

In addition, we also explain and tell people during training how to handle the equipment, for which it is necessary to carry out maintenance, as you can foresee and predict failures with proper maintenance. For example, if dust and dirt is not cleaned out, the machine service life is shortened, which is undesirable: the machine works much better and more reliably when properly maintained.

- Is the above stated clearly in the operation manual?

– Yes, we have described all details in the operating manual, including the procedure and frequency of maintenance. However, according to the old Russian tradition, people often turn to the operating manual only after the failure at hand due to no maintenance. In their opinion, the machine should work itself, constantly and at all times. Along with commissioning, the plant offers service and technical maintenance, which eliminate, first of all, the sources of major concerns of the clients, because they are sure that the machine will be serviced by specialists, advising on competent operation, and the equipment response will be its reliable and smooth operation.

The machine works much better and more reliably with proper and timely maintenance.

Summarizing the above, a noteworthy detail is that entrusting commissioning works to professionals is preferable: either to the plant maintenance service or the authorized service centers in the regions, which number is huge. There is a hotline for prompt resolution of urgent issues related to setup, operation and proper maintenance of «Vyazma» equipment, call it and be sure to get a qualified response from the staff with extensive experience in installation of our equipment.

Toll-free numbers:

+7 (915) 646-08-08, (915) 646-09-09, (910) 720-28-84

215110 Russia, Smolensk region

Vyazma, 25th October Str., h. 37

Tel: +7 (48131) 3-48-12

E-mail: vmz@vyazma.su